Custom Spicy Sausage Snack Food Packaging

Product Advantages & Features

1. Advantages

- Neon film draws Gen‑Z eye; trial sales show +28% lift with sausage snack food packaging refresh.

- Hot‑fill laminate withstands 90 °C filling for spicy meat packaging safety.

- Flexible meat snack pack with hang‑hole supports omnichannel displays.

2. Features

(1) Basic Information

- Material: Food‑grade PET/PE (structure varies; contact us for spec sheet)

- Colors: neon green

- Size: 80 × 120 mm

- Thickness: 60 µm ± 5 µm

- Finish: Matte/Gloss selectable

(2) Basic Characteristics

- This Sausage snack food packaging achieves the ideal balance between shelf impact and barrier performance. Laser scoring offers effortless opening, while rounded corners improve consumer safety and packaging line efficiency.

(3) Basic Functions

- Insert one cooked sausage (≤25 g), vacuum or MAP seal at 90 °C; Euro‑slot allows peg display; microwave‑safe for 30 s reheat.

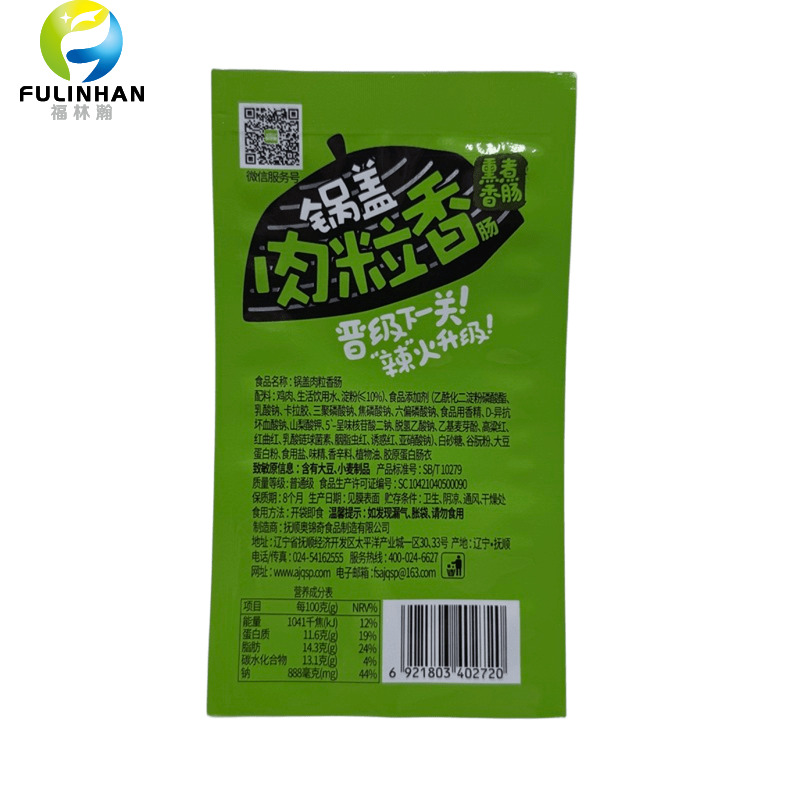

Product Images

Product Parameter Table

| Parameter |

Details |

| Material |

PET/AL/LLDPE |

| Color |

neon green |

| Size |

80 × 120 mm |

| Thickness |

60 µm |

| Barrier |

≤0.5 cc/m²·day OTR |

| Closure |

Heat seal |

Product Application Range

1. Suitable Users & Products

- DTC brands, specialty retailers, and co‑packers

2. Scenes & Projects

- Subscription boxes, gift sets, travel retail

Company Advantages & Strengths

1. Scale & Compliance

- 10,000 m² ISO‑22000 & BRC‑certified plant, FDA‑registered films.

2. Capacity

- 500 million pouches annually, 8 high‑speed rotogravure lines, 3 digital short‑run presses.

3. Export Track Record

- 18 years, 40+ developed‑market countries, OTIF 98.6%.

4. Honors

- Top 50 Asian Flexible Packagers 2024, EcoVadis Silver.

5. Service & After‑Sales

- OEM/ODM from dieline to doorstep; 3‑day free plain samples; 15‑day rapid tooling; MOQ 5,000; defect‑free guarantee or 110% credit.

6. Assurance

- SGS raw‑material traceability, ASTM & EU 1935/2004 compliance, full NDAs for bespoke designs.

FAQ

- Q1: Are your films food‑grade and compliant with FDA, EU 1935/2004, and CFIA standards?

- A1: Yes. All laminates are certified food‑contact safe and include third‑party test reports on request.

- Q2: What oxygen and moisture barrier levels can your structures achieve?

- A2: Standard high‑barrier pouches reach ≤ 0.5 cc/m²·day OTR and ≤ 2 g/m²·day WVTR at 23 °C/65 % RH; ultra‑barrier formulas can go lower.

- Q3: Are your pouches suitable for retort, hot‑fill, or microwave applications?

- A3: We engineer specific laminates for each process—retortable up to 121 °C/30 min, hot‑fill up to 95 °C, and metal‑free microwave‑safe films.

- Q4: What printing capabilities do you offer for small and large runs?

- A4: Digital inkjet up to 1200 dpi for MOQ 5,000 and rotogravure up to 9 colors ΔE≤2 for mass production.

- Q5: Can you produce recyclable or compostable packaging?

- A5: Absolutely. We offer mono‑material PE/PE or PP/PP recyclable pouches and certified home‑compostable PLA‑based options.